Ozone Treatment Technology

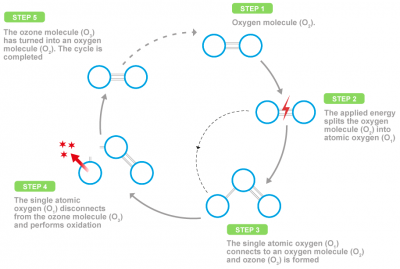

Ozone is made up by oxygen and will revert back into oxygen upon reaction.

Ozone Treatment Technology

Ozone is used in water treatment due to its disinfection and oxidisation properties. Ozone is a short-lived triatomic (O3) form of oxygen created by electrically charging oxygen molecules. It can be formed naturally in the environment or artificially using ozone generators. Ozone is a very effective disinfectant because it kills bacteria, viruses, protozoa, fungi, & algae. The oxidisation potential of ozone removes metals such as iron, manganese & sulphur, and decreases colours and odours in water. Ozone decreases the biochemical oxygen demand (BOD) and chemical oxygen demand (COD) in water through oxidising organic matter. Ozonation of water also causes a micro-flocculation effect increasing the effectiveness of filtration and coagulation processes. Ozone is short-lived and breaks down to atmospheric oxygen. Ozone is used in potable, wastewater, and industrial water applications.

Our clients have purchased ozone units for:

- Disinfection

- BOD5/COD reduction

- Remove colours (including tannins) and odours from water

- Reduce the concentration of pharmaceuticals and personal care products

- PFOS/PFAS treatment

- Decrease the transport of chemicals to site

- Lessening of chemical taste in water treatment

Our clients have been from a wide range of sectors, including;

- Drinking & wastewater treatment plants

- Mining & gas

- Food & beverage industry

- Aquaculture

- Hydroponics

- Irrigation (including with recycled water)

- Groundwater treatment (metals, PFOS/PFAS)

- Ozone operation

- Ozone treatment system

- Primozone equipment as part of the ozone treatment system

- Primeozone installation at York WTP

- York WTP Primeozone installation

- ClearWater Tech Ozone Generator

- Ben Kele and Tony Kodel visit the Mazzei booth at WEFTEC22

Ozone was first used in a municipal drinking water facility in 1906, in Nice, France. It has continued to be used and new technological advances have transformed ozone water treatment into an increasingly common best practice solution.

The technologies we supply produce ozone on-site by using an ozone generator. No oxygen or other chemicals need to be brought to site. We use Mazzei venturi injectors to mix ozone gas. Mazzei injectors provide a very energy efficient mixing method which produces a microbubble of ozone with a high surface area.

Arris supplies Primozone and ClearWater Tech ozone units. These technologies are robust and reliable and these manufacturers provide full support for their products.

Typically, we supply ClearWater Tech units for smaller installations and Primozone for large volume applications. We can design, supply, install, operate and maintain these systems. We have trained staff who travel Australia-wide. Please contact us with your ozone enquires so we can assist you further.

To find out more about ozone treatment

as well as other Arris water treatment

technologies, click here.

Contact Arris to find out more about

our specialised water technology solutions.